Kunstleder, auch bekannt als Synthetikleder oder Imitationsleder, ist ein Material, das natürlichem Leder in Aussehen und Haptik sehr ähnelt, aber vollständig synthetisch hergestellt wird. Es wird typischerweise durch Aufbringen oder Imprägnieren eines Polymerharzes (hauptsächlich PVC oder PU) auf ein Textilgewebe produziert. Anschließend durchläuft das Material Prozesse wie Schäumen, Prägen, Färben und Oberflächenbehandlung.

Im Vergleich zu traditionellem Naturleder bietet Kunstleder erhebliche Vorteile hinsichtlich Kosten, Umweltbelastung und Produktionsprozessen. Daher findet es breite Anwendung in verschiedenen Bereichen, wie beispielsweise bei der Taschenherstellung, der Möbelproduktion und der Herstellung von Fahrzeuginnenausstattungen.

Heute wollen wir uns mit dem Produktionsprozess von Kunstleder und der dahinterstehenden Technologie beschäftigen.

Das Trägermaterial von Kunstleder ist die unterste Schicht, die die Textur, Flexibilität und Haltbarkeit des Kunstleders bestimmt. Gängige Trägermaterialien für Kunstleder sind beispielsweise:

Die Polymerrezeptur für Kunstleder ist typischerweise eine Kombination aus synthetischen Polymeren und verschiedenen Additiven, um die gewünschten Eigenschaften wie Flexibilität, Abriebfestigkeit, Wasserdichtigkeit usw. zu erzielen. Nachfolgend sind gängige Polymerrezepturen für Kunstleder und ihre Komponenten aufgeführt:

(1) Rezeptur für Kunstleder aus Polyvinylchlorid (PVC)

PVC-Kunstleder ist eine der gängigsten Arten. Seine Polymerzusammensetzung umfasst typischerweise folgende Komponenten:

PVC-Kunstleder wird aufgrund seiner Haltbarkeit, Wasserbeständigkeit und einfachen Reinigung häufig für verschiedene Arten von Taschen verwendet, wie zum Beispiel Handtaschen aus Kunstleder, Trolleysund verschiedene Werkzeugtaschen aus Leder.

(2) Polyurethan (PU) Kunstleder-Rezeptur

Kunstleder aus PU Es ähnelt in seiner Textur eher natürlichem Leder als PVC und wird häufig für hochwertige Lederprodukte verwendet. Seine Zusammensetzung umfasst typischerweise:

PU-Kunstleder wird aufgrund seiner Weichheit, seines Aussehens, das Naturleder ähnelt, und seiner relativ umweltfreundlichen Eigenschaften häufig bei der Herstellung verschiedener Taschen, wie zum Beispiel Clutch-Taschen und Abendtaschen, verwendet.

(3) Rezeptur für thermoplastisches Polyurethan (TPU)-Kunstleder

Thermoplastisches Polyurethan (TPU)-Kunstleder zeichnet sich durch hohe Flexibilität und Abriebfestigkeit aus und wird häufig für Produkte wie Schuhe und Sportartikel verwendet. Zu den gängigen Komponenten gehören:

(4) Andere gebräuchliche Polymerformulierungen

Neben PVC, PU und TPU gibt es weitere Polymerarten, die bei der Herstellung von Kunstleder verwendet werden können, wie zum Beispiel:

Einer der Kernprozesse bei der Herstellung von Kunstleder ist die Beschichtung. Am Beispiel von PVC umfasst der Produktionsprozess typischerweise die folgenden Schritte:

1. Rohstoffmischung: PVC-Harz, Weichmacher, Stabilisatoren, Pigmente und andere Rohstoffe werden im richtigen Verhältnis gemischt, um eine Beschichtungsmasse herzustellen.

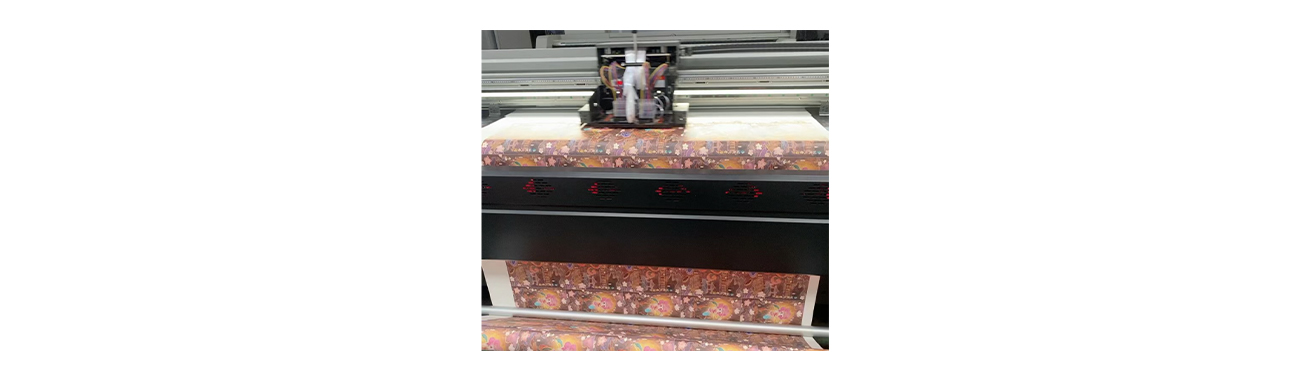

2. Beschichtung: Die Beschichtungsmischung wird gleichmäßig auf das Substrat (z. B. Textilgewebe) aufgetragen. Während des Beschichtungsprozesses werden typischerweise mechanische Geräte wie Walzen oder Rakel eingesetzt, um die Beschichtung auf der Gewebeoberfläche zu verteilen und eine gleichmäßige Schicht zu bilden.

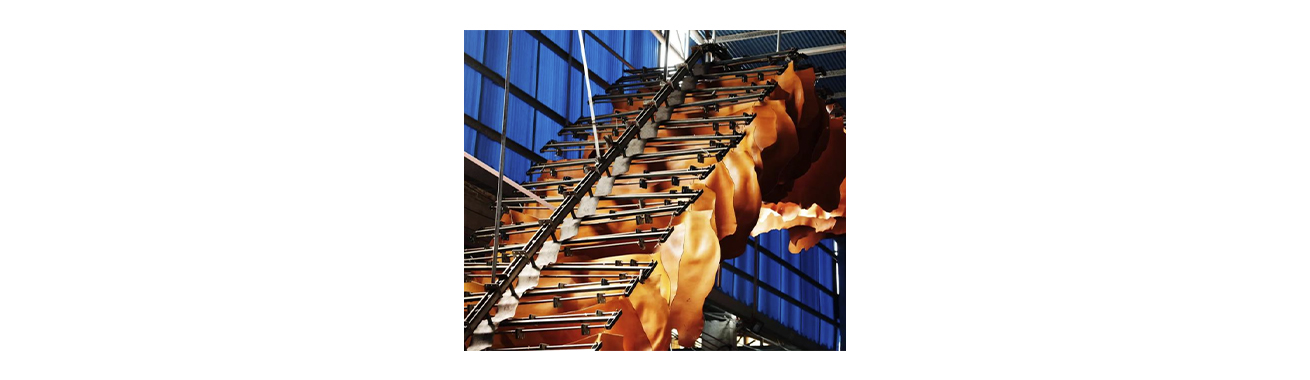

3. Erhitzen und Aushärten: Das beschichtete Substrat wird erhitzt, um das Lösungsmittel in der Beschichtung zu verdampfen, wodurch eine feste Kunststoffschicht entsteht. Dieses Verfahren gewährleistet eine feste Verbindung der Beschichtung mit dem Substrat und verleiht ihm das Aussehen und die Haptik von Leder.

4. Prägen und Polieren: Um die Textur und Haptik von Naturleder nachzuahmen, werden mithilfe von Prägemaschinen häufig verschiedene Muster in die Oberfläche von Kunstleder eingeprägt. Zusätzlich kann die Oberfläche mit einem Glanz- oder wasserabweisenden Mittel behandelt werden, um ihr Aussehen und ihre Haltbarkeit zu verbessern.

Während des Produktionsprozesses durchläuft Kunstleder zudem mehrere Nachbehandlungsschritte, um seine Qualität und Funktionalität zu verbessern. Zu den gängigen Nachbehandlungsschritten gehören:

1. Heißpressen und Abkühlen: Um die Festigkeit und Flexibilität von Kunstleder zu verbessern, wird es üblicherweise einem Heißpressverfahren unterzogen. Dadurch entsteht eine widerstandsfähigere Materialstruktur.

2. Beschichtungsbehandlung: Einige Kunstlederprodukte erhalten zusätzliche Beschichtungen, wie z. B. wasserdichte oder UV-beständige Beschichtungen, um ihre Haltbarkeit und ihren Tragekomfort zu verbessern.

3. Färben und Sprühen: Wenn bestimmte Farbeffekte gewünscht sind, kann die Oberfläche des Kunstleders gefärbt oder besprüht werden, um die Farbe lebendiger und gleichmäßiger zu machen.

Die Qualitätskontrolle ist im Produktionsprozess von entscheidender Bedeutung. Um sicherzustellen, dass das Kunstleder die erforderlichen Standards erfüllt, werden in der Regel strenge Tests durchgeführt:

1. Abriebfestigkeitsprüfung: Dieser Test misst die Abriebfestigkeit von Kunstleder, insbesondere für Produkte wie Taschen und Schuhe, die über längere Zeit Reibung ausgesetzt sind.

2. Zugfestigkeitsprüfung: Dieser Test prüft, ob das Kunstleder unter Dehnung reißt oder bricht.

3. Feuchtigkeits- und Luftfeuchtigkeitstest: Gewährleistet, dass sich das Kunstleder in feuchten oder nassen Umgebungen nicht verformt oder verschlechtert.

4. Umweltprüfung: Prüft, ob die im Produktionsprozess verwendeten Materialien den Umweltstandards entsprechen und ob sie Schadstoffe enthalten.

Da Umweltschutz und Tierschutz immer wichtiger werden, entscheiden sich immer mehr Marken und Verbraucher für Kunstleder. Kunstleder sieht nicht nur aus wie Naturleder, sondern bietet auch Vorteile in Bezug auf Kosten, Pflege und Haltbarkeit. Es findet breite Anwendung in folgenden Bereichen:

Zusammenfassend lässt sich sagen, dass die Anwendungsperspektiven von Kunstleder dank kontinuierlicher Verbesserungen der Produktionsprozesse und steigender Anforderungen an den Umweltschutz sehr vielversprechend sind. Von der Rohstoffauswahl über Beschichtungsverfahren und Nachbehandlung bis hin zur Qualitätsprüfung – jeder Schritt erfordert präzise Handwerkskunst und modernste Technologie. Mit dem Aufkommen innovativerer Techniken wird Kunstleder zukünftig in immer mehr Bereichen seine einzigartige Attraktivität unter Beweis stellen und zu einem unverzichtbaren Bestandteil des Alltags werden. Mehr erfahren individuell gestaltete Tasche aus Synberry schnell.

| Autor | ||||||

|

Copyright

@2024 Synberry Bag & Package Products Co.,Ltd Alle Rechte vorbehalten

.

NETZWERK UNTERSTÜTZT

NETZWERK UNTERSTÜTZT

Sitemap / Blog / Xml / Datenschutzrichtlinie